In our assembly we complete your individual product made of sheet metal

Great variety of mounting assemblies

The sheet metal and bent parts manufactured in the upstream production become a unit with various components in the assembly at BVS Systemtechnik. Our experienced fitters assemble the previously lasered, punched, bent and welded individual parts as a housing or complete end product. Products are created for almost every field of application: whether for the electrical engineering industry, mechanical engineering, medical technology, measurement technology, for flight seats or information systems – we manufacture your individual system in almost unlimited variety.

All-round project support

Our project support is available for extensive tasks. From the drawing to the installation of the provided or self-procured components, we coordinate the ideal complete solution in close contact with the customer.

Our project support is available for extensive tasks. From the drawing to the installation of the provided or self-procured components, we coordinate the ideal complete solution in close contact with the customer.

Assembly in workshop manner

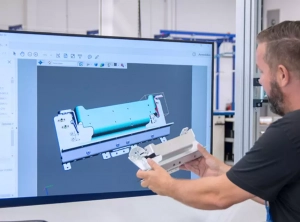

Depending on the complexity of the end product, the fitters at BVS adapt their workstations to find the ideal process sequence for the respective assembly. The individual workstations are equipped with height-adjustable assembly tables and computer systems. Via the digital archive, the fitters call up the 3D models and find assembly instructions documented in pictures for the optimum assembly of the enclosures.

At various assembly stations, BVS manufactures, for example, an airplane seat assembly consisting of a large number of individual parts, including stamped aluminum parts, clip nuts, rivets, edge protection, milled and turned parts. The complete assembly is integrated into the flight seats at the end customer and is used to store consumer electronics, table and life jackets.

The high number of variants of assemblies will be flexibly processed using assembly islands. Even small quantities can be efficiently inserted in the workshop production at BVS.

Experienced technical personnel

The experienced team of industrial mechanics and mechatronic engineers stands for the professional assembly of the modules. With their specialist training, internal and external training courses and the intensive know-how gained from practical experience, they assemble a wide range of housings and end devices for a wide range of applications.

The experienced team of industrial mechanics and mechatronic engineers stands for the professional assembly of the modules. With their specialist training, internal and external training courses and the intensive know-how gained from practical experience, they assemble a wide range of housings and end devices for a wide range of applications.

In order to cope with this abundance of products, BVS continuously adapts the assembly processes. The optimisation of the fixtures, intermediate storage and material flow and the constant training of our personnel ensures an economic and high-quality result for the assembly of components at BVS Systemtechnik.

Would you like advice on the assembly of your module or a complete system?

Our technical consultants will be pleased to assist you.

BVS Systemtechnik GmbH

Ludwig-Bölkow-Str. 14

D-19061 Schwerin

Fon: +49 (0) 385 / 7733 88- 0

E-mail: systemtechnik@bvs-gruppe.de