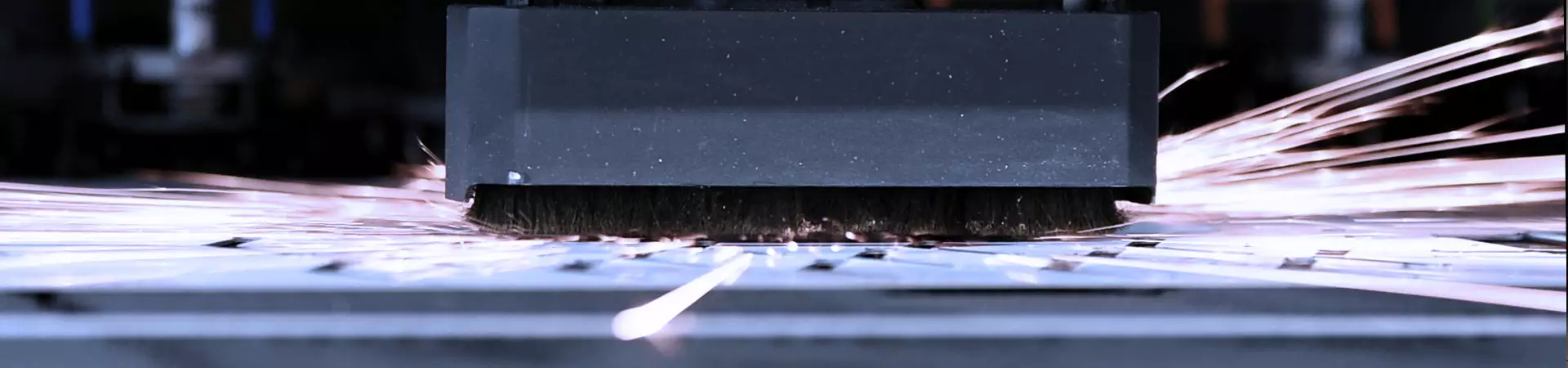

Punching/Laser cutting of thin sheets

With the two punch-laser combination machines truMatic 6000, fibre laser we process a wide range of parts in small batch sizes as well as in large series. The punching head processes standard contours and formations such as lugs or threads. The laser cuts high-quality outer contours and filigree inner contours.

The punch-laser combination machine combines highest process reliability and flexibility.

The solid-state laser processes various metallic materials such as aluminum, stainless steel, steel, titanium and various non-ferrous metals up to 6 mm material thickness with cutting speeds of up to 34 m/min.

The solid-state laser processes various metallic materials such as aluminum, stainless steel, steel, titanium and various non-ferrous metals up to 6 mm material thickness with cutting speeds of up to 34 m/min.

The machine is directly connected to the fully automatic high-bay warehouse. In addition, handling components are installed for loading/unloading of raw material and finished parts. The extensive tool storage for tool change during machining time enables an automated production flow. Sheet metal formats of up to 3,000 x 1,500 mm can be processed. The machine control is equipped with integrated order and tool management.