From welding robot to grinding robot

Project: The story of a welding robot that turns into a grinding robot…

Schwerin: 19.10.2023: Robots in industry are often very versatile and changeable. Over the summer, this resulted in a very exciting project at BVS Systemtechnik in Schwerin.

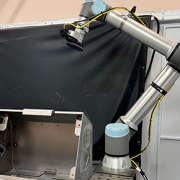

A welding robot has completed further training in grinding and now contributes very successfully to the on-time implementation of orders with an expanded task profile.

How did the idea come about? What is the intention?

The project was born out of necessity, in order to achieve a large number of pieces even with a small number of personnel, while reducing the amount of manual work.

What does the implementation look like?

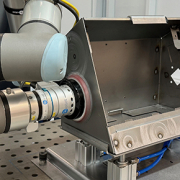

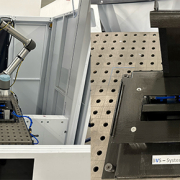

A cell now starts welding, after which the product is automatically clamped and ground. In this way, two work steps can be successfully implemented in one without having to store parts in between.

What are the advantages of the project?

The employee in charge does not need any protective equipment and is no longer exposed to the welding gases as well as the grinding dust. This significantly improves occupational safety.

What investment was made?

Four jigs, one conversion kit (special grinding head) and one grinding head were invested. The fixture was rebuilt, and programming took place internally.