How can a Lissmac grinding machine be tuned?

The next interesting project, which is briefly presented here, is also focused on automation processes in industry.

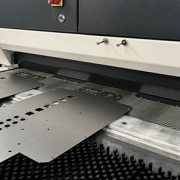

To operate a Lissmac grinding machine in metal processing, two people are normally required, i.e. one person “feeds” the machine with sheets that need to be ground, a second person receives the finished sheets at the other end of the machine.

How can the process be optimized and shortened?

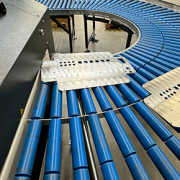

A conveyor belt was built for the Lissmac grinder to reduce the amount of manual work. Now the machine is only “fed” with material by one employee, after completion the sheet rolls back to the employee on the retrofitted conveyor belt and can be taken to the next station.

What are the advantages of the tuned machine?

In this way, the machine can be better utilized and produce a higher number of pieces. The working time per production part is halved. Employees’ commutes are reduced. This way, time and costs can be saved efficiently.

What investment was made?

A conveyor belt for the machine was retrofitted.